Apr 16, 2025 // Kira Biernat

Navigating Change in the Container Terminal Industry

Trends and Truths from CTAC 2025

Jan 9, 2023 Zdravka Ley

ShareEarly on, mankind had to learn how to economize. This is because goods are usually scarce but human wants and needs are practically unlimited. According to the "economic principle", a society should use scarce goods in such a way that it achieves the best possible balance between the satisfaction of needs and the consumption of goods. Today, sustainability aspects also significantly influence this balance.

How optimization algorithms can support logistics in the balancing act between the availability of goods, economic efficiency, and sustainability is illustrated by the practical example of the creation of a supply network for an automobile manufacturer.

Companies need to be successful but they also have a responsibility to their employees and the environment. They must pursue these three objectives in an optimally coordinated manner. Innovations and infrastructure development support sustainable and resource-conserving industrial development. How closely these three areas are linked is underlined by UN Sustainable Development Goal 9, which advocates promoting industrialization, supporting innovation, and expanding infrastructure.

Advanced information and communication technologies can make an important contribution to sustainable industrial growth by contributing to the company’s transparency, efficiency, and resilience. With its logistics solutions based on operations research and artificial intelligence, INFORM has been supporting industrial companies in this for over 50 years. These optimization algorithms work with current data from day-to-day business and provide reliable forecasts, as well as dependable recommendations for action for efficient and sustainable business.

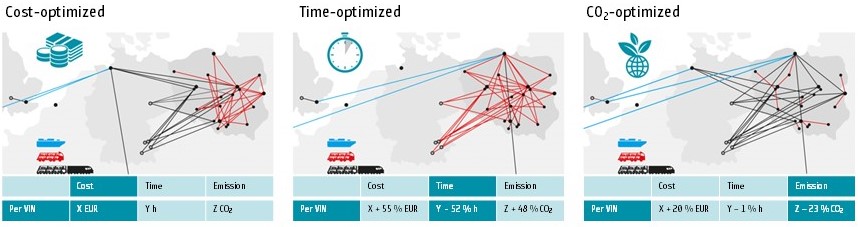

The following practical example of the creation of a delivery network shows how industrialization, innovations, and infrastructure interact optimally. It is based on an INFORM case study for the transport of a car manufacturer's globally produced vehicles to car dealerships in the Polish market. The goal of the study was to calculate optimal configurations of the distribution infrastructure based on various criteria, priorities, and weighting. The algorithm had to consider costs, delivery times, and CO2 emissions on the one hand, and the existing infrastructure - ports, storage and transshipment points, shipping, train, and truck transport options - on the other.

Three possible, feasible scenarios were created:

1. Optimal costs

Cost optimization can be achieved, for example, by consolidating shipments and shipping them to a single port. From this port, onward transportation to warehouses and transshipment points can be made by rail. From there, cars are delivered to dealers by truck.

2. Shortest delivery times

If shortest transport times are prioritized, it is recommended to use truck transports directly from the port. However, this scenario is more costly and emission-intensive.

3. Low CO2 emissions

In order to transport the deliveries with the lowest possible emissions, the algorithm recommends ship transports to regional ports and onward transport by train. Trucks are only used for the last mile to the dealer.

For all three scenarios, optimization algorithms deliver significant improvements over traditional planning processes, and the goals do not have to be mutually exclusive. Car manufacturers can weight them differently to achieve a good balance of low emissions, low costs, and short delivery times. In this way, they increase their sustainability without causing uncontrollable costs or delivery times.

Optimization algorithms will also support future developments. It is not far-fetched that we, as car buyers, will soon determine ourselves how high the CO2 footprint of our car delivery should be.

What mix of sustainability, cost, and speed would you choose?

About our Expert

Zdravka Ley

Marketing Manager

Zdravka Ley started working for INFORM in 2002 and is focused in topics around the optimization and sustainability of delivery and internal transport logistics.