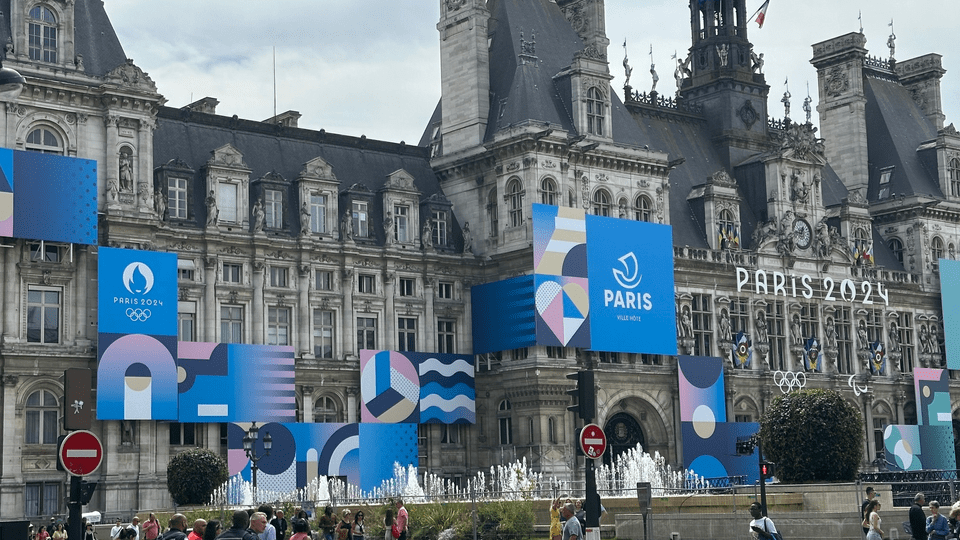

This year's Olympic Games will open in Paris on July 26. With the lighting of the Olympic flame, a global competition begins that includes 329 medal decisions in more than 40 sports. From traditional disciplines such as athletics and swimming to new ones such as skateboarding and sport climbing, each competition is a result of precise planning and excellent execution.

The various competitions not only pose a challenge to the infrastructure and venues, but also require a logistical masterpiece. Every detail, from the organization of the individual competition to the awarding of medals, must run flawlessly in order to avoid delays and problems. Coordination involves a large number of participants, processes and means of transportation - a scenario that is also familiar in inplant logistics. Efficient planning and control, which is essential for competitions, is also fundamental for effective and trouble-free processes in inplant logistics. However, we must not lose sight of the overall event when considering trouble-free individual competitions - the success of the Olympic Games is paramount. This holistic perspective is also crucial when we look at the efficiency and effectiveness of inplant logistics.

Beyond stand-alone solutions: the holistic digitalization of inplant logistics

Just as the focus at the Olympic Games is on coordinating the overall event, uninterrupted production supply is also essential in inplant logistics. Unforeseeable events must be responded quickly and efficiently. In production logistics, such events are part of everyday business, be it due to machine breakdowns, delivery delays or production changes. Despite these imponderables, production supply must be ensured efficiently, which requires precise and flexible management.

In many companies, so-called digitalization islands have been created to date, in which sub-areas or sub-processes have been digitalized and automated. Although these isolated solutions offer advantages, they have their limits when it comes to achieving holistic optimization of logistics processes. The future belongs to complete digitalization, which not only includes the automation of individual steps, but above all promotes seamless communication between all systems involved and focuses on the overall optimum.

Optimization spreads like wildfire

The complexity of the Olympic Games increases with every new Olympic sport. This also applies to intralogistics processes. Due to increasing product diversity and new production processes, the number of transport vehicles used is growing - from classic forklifts to tugger trains, trucks, cranes and various AGVs. Without advanced intralogistics management systems, which serve as a central logistics control to seamlessly connect the various digitalized processes within a company, it is impossible to achieve optimum inplant logistics.

Intralogistics management systems play a crucial role by enabling consistent and efficient control of all logistics processes. By integrating and analyzing real-time data from all areas of the logistics chain, intralogistics management systems can not only optimize transport order scheduling, but also react quickly to changes in operational processes. They minimize empty runs and maximize the utilization of the means of transport, which also leads to significant cost savings.

The SYNCROTESS intralogistics management system supports decision-making with advanced algorithms based on artificial intelligence, enabling proactive planning and management. SYNCROTESS processes all relevant information for scheduling in real time, including the status of all vehicles, the current transport order list with all technical constraints, distances, loading capacities as well as deadlines and priorities. This comprehensive data basis makes it possible to calculate the optimum transport sequence and manage resources efficiently. Even more complex logistical challenges, such as multi-stage transportation across different warehouse levels and locations, are efficiently managed by the system. This enables complete control of the entire internal material flow from the ramp to the assembly line and creates the basis for agile and resilient inplant logistics of the future.

AI as a further driver of efficiency in inplant logistics

In today's data-driven world, artificial intelligence (AI) is fundamentally changing how companies manage their logistics processes. AI systems not only enable comprehensive and immediate availability of data, but also a new approach to planning and execution in inplant logistics. In contrast to traditional methods, which often operate in isolation in the areas of sales, production and logistics planning, AI promotes the integration of these systems. This integration expands opportunities to optimize the entire supply chain by enabling closer and more efficient collaboration between producers and suppliers. Just as direct human interaction dominated business processes 40 years ago, AI now offers new opportunities for interaction between previously separate systems. By automating data evaluation and interpretation, AI improves decision-making, minimizes delays and increases responsiveness to market changes. These advanced AI solutions can lead inplant logistics to new levels of efficiency and agility.

CONCLUSION

As with the Olympic Games, where the spotlight is not on the individual competitions but on the event as a whole, inplant logistics must also look beyond individual digital improvements to a comprehensive overall solution. Modern technologies such as intelligent intralogistics management systems with artificial intelligence are crucial to not only optimize isolated processes, but to create a seamlessly integrated logistics network.

At a time when efficiency and agility are decisive competitive advantages, the further development of inplant logistics is essential. The challenge is to achieve excellence not only in individual areas, but at all levels of the supply chain.

Are you using technological advances to put your inplant logistics on the winner's podium?