Yard management software is the heart of smooth plant logistics. Just like a precise watch mechanism, this software coordinates and controls the processes from check-in to exit on the plant premises, supports the logistics managers in their day-to-day work, and ensures seamless logistics.

Unforeseen events are part of everyday life in yard logistics: delivery vehicles arrive too early, too late, or unannounced, bring different material or in a different quantity than announced - and slots get mixed up, loading and unloading points on the plant premises have to be rescheduled. These challenges can only be mastered efficiently with the use of efficient yard management software.

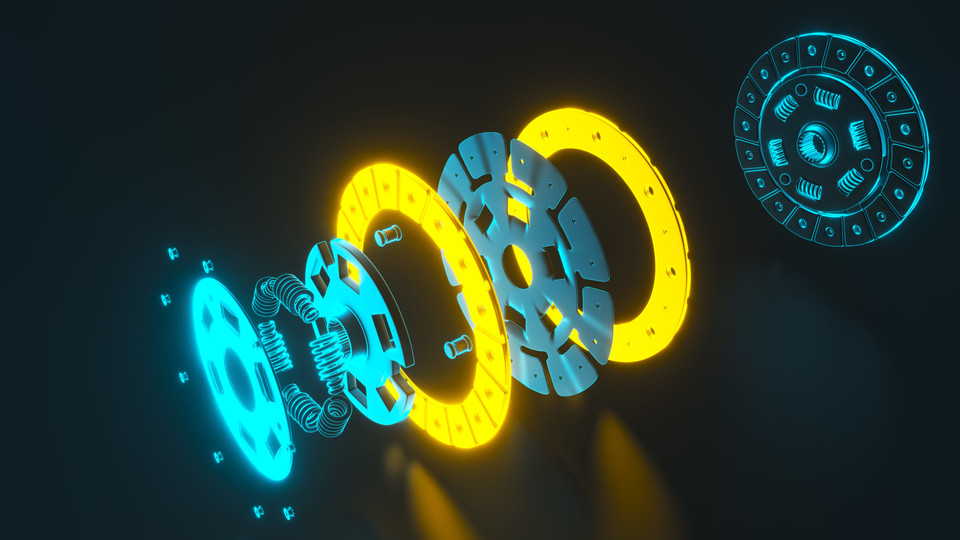

EVERY COGWHEEL IN VIEW

A watch mechanism consists of various mechanical components. Thanks to the precision and interaction of the spring, gears, and escapement, a watch movement can reliably measure and display the time.

Like a watch mechanism, yard management software can also ensure precise and efficient handling of plant logistics if all processes are considered. Let's take a closer look at seven important cogs of yard management software.

1. Flexible check-in:

Check-in at the plant gate is carried out digitally in a similar way to check-in at the airport: at special communication terminals, via an app on the driver's smartphone, or on the company's own end devices. This means that data is recorded digitally and time-consuming manual processes and any language barriers between drivers and gatekeepers are eliminated.

2. Independent optimization of the throughput:

The software automatically calculates new plans if a truck misses its time slot. The software not only considers the specific truck and the priority of its load but also the status of all vehicles on the factory site and in the incoming goods area, as well as the utilization of the loading points, in order to determine an optimum throughput sequence.

3. Automated communication:

The updated throughput sequence is automatically communicated to all parties involved to ensure smooth processing. The truck drivers are informed immediately which loading point, buffer zone, or car park to head for. At the same time, the loading point employees are notified of which goods they need to dispatch, when, and in which order.

4. Additional services via app:

Smartphone apps offer truck drivers and loading point operators additional functionality such as logging ADR checks, scanning loads and packages, or locating trucks as they approach the site.

5. Integrated inbound and outbound planning:

An intelligent yard management system not only organizes truck arrivals and loading or unloading processes. It also controls the integrated planning of inbound and outbound traffic, such as the simultaneous delivery of empty containers and collection of goods. It is also possible to link pick-up and delivery time slots as part of a joint logistics network between supplier and manufacturer.

6. Variable connection and integration options:

The system can be easily integrated into existing IT systems via standard interfaces. This allows information to be synchronized and provides meaningful statistics for management reporting. Appropriate software components can also be used to coordinate upstream trailer yards or integrate an intralogistics management system, which can then be used to synchronize internal logistics with delivery logistics.

7. Scalability to meet requirements:

The yard management system can be flexibly adapted and scaled to the specific requirements of a company. It considers industry-specific differences and enables simple adaptation to different quantity structures and requirements.

NEW HORIZONS FOR YOUR LOGISTICS

An intelligent yard management system is more than just software - it is the heart of a smoothly functioning plant operation. By precisely coordinating and controlling all logistical processes from check-in to exit on the factory premises, it ensures seamless logistics and enables companies to react flexibly to unforeseen events. With every gear perfectly interlocking, efficient yard management software creates transparency, reduces throughput times, and saves resources in time, materials, and personnel.

Are you ready for more efficient plant logistics?

Find out more about how our yard management software can support your company.