Is it only human that knowledge alone is usually not enough to initiate change? And isn't the greatest danger always when risks are misjudged? There is a consensus on the finite nature of our resources and the urgent need for sustainable management. The global community has included "UN Sustainable Development Goal 12 - Responsible Consumption and Production" in its 2030 Agenda for Sustainable Development.

In addition to the efficient use of natural resources, it also addresses the reduction of waste and the mandatory reporting of sustainability information. The demand from society to politics and industry for more transparency on the material footprint of products has become loud. Can solutions that have already been implemented rapidly provide transparency and assist in the sustainable use of resources?

VISUALIZE EXISTING DATA

A recent short survey by ‘Deutschen Verkehrszeitung‘ makes clear that only a quarter of the participants know the CO2 emissions in their companies. And one-third currently have no plans whatsoever for measures to determine this. This is a surprising result because even solutions that have already been implemented in the company can help to calculate data on CO2 emissions from the production of raw materials to production, storage, and transport.

Here, logistics can become a pioneer. According to a survey by the International Energy Agency, transport accounted for 23 percent of global greenhouse gas emissions in 2021. This has made efforts to achieve "greener logistics" all the greater in recent years. Many companies are already measuring their footprint and using data from their transportation management systems. Real-time IT systems in logistics, moreover, can not only report this data but also help improve the carbon footprint and sustainably use existing resources. How real-time IT in logistics serves the aforementioned Sustainable Development Goal 12 is illustrated by an example from internal transport logistics.

USING EXISTING RESOURCES SUSTAINABLY

Collecting data and visualizing it is the first important step in ensuring sustainable and efficient use of resources in plant logistics. The second step requires systems that plan predictively and detect critical events in real time in order to react accordingly in a fast, optimized, and resource-saving manner.

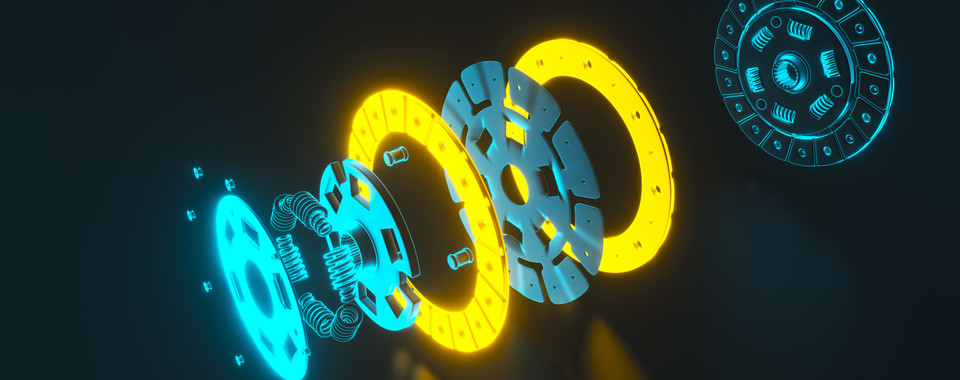

A transport control system has the task of optimally controlling the in-plant vehicle fleet (forklifts, driverless transport vehicles, route trains, etc.). The forklift truck, developed in 1917 as a platform truck with an internal combustion engine, is still the most common tool when it comes to transporting materials in production logistics.

Forklifts are designed for an economic service life of eight years. However, manufacturers calculate the forklift's service life at somewhere between 10,000 to 15,000 operating hours. This is because after that, the engine and transmission require more care and maintenance, and the first parts need to be replaced. Therefore, it is important to use the operating hours optimally for the core task of material transportation.

An intelligent transport control system combines all relevant information from resources and transport orders and synchronizes the processes. By bundling transport orders and reducing search trips, forklift productivity increases while decreasing operating hours. This minimizes the use of resources while maximizing transport performance. With such a system, an average forklift usage reduction of 25 percent can be achieved, which makes both ecological and economic sense.

CONCLUSION

Careful use of existing resources in logistics can be made simple and sustainable with the help of the right real-time IT tools. The results of our survey of 300 logistics experts are clear: 88 percent of respondents are convinced that companies will be better positioned in the market in five years' time thanks to real-time IT. In practice, however, only 26 percent of companies are currently using concrete real-time applications that could also contribute to resource conservation in logistics.

What hurdles does your company have to overcome on the way to more sustainable resource utilization in logistics?